Ductile metal Brass - a historical digression, basic properties, characteristics and photos of the alloy

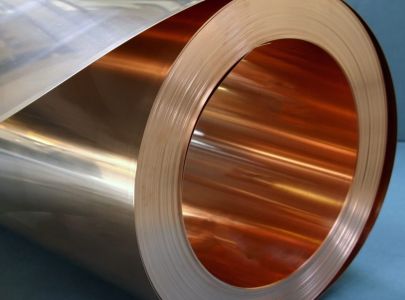

Brass is a metal material based on copper and an alloying component zinc. The alloy may contain lead, iron, nickel elements. Sometimes tin is present, but in small quantities. According to the metallurgical table, brass does not belong to the bronze group.

Story

The chemical element zinc was discovered in the 16th century, but the yellow metal was well known to mankind many centuries before that moment. The ancient peoples who lived in the southern Black Sea region combined copper with smithsonite, zinc ore, to obtain a brass alloy.

During the time of the Roman politician Augustus, brass was referred to as "orychalk", which literally means "golden copper". The yellow metal is similar to gold; ancient Roman coins were printed from it, jewelry and household items were made.

At the end of the 18th century, the English scientist D. Emerson obtained brass by alloying copper with industrial zinc. He patented the method and received a British patent. In the 18th century, before the widespread use of brass in metallurgy, it was used to counterfeit gold in Western Europe and Russia.

The main characteristics of brass

Brass combines the positive properties and advantages of composite metals.Metallurgists use the material in industry to improve the properties of metals that are collectively stronger than individually. The yellow metal has resistance to corrosion processes, increased strength, and can be in aqueous and alkaline solutions for a long time without damage.

Chemical properties

The structure of brass is formed by two classical components - zinc, copper. In the traditional version, the proportion of copper does not exceed 70%, and zinc - 30%. Several grades of technological brass have been developed, in which the zinc content is less, only 48%. In the steel industry, almost half of all zinc used is recovered from waste and recycling.

There are two types of brass with differences in internal structure and chemical composition:

- alpha type (single-phase), zinc content 35 percent;

- alpha-beta type (two-phase), in an alloy of 50% zinc and 6% lead.

Brass in external characteristics is similar to some brands of bronze, but does not belong to bronze materials.

The composition of special grades of brass alloys contains tin in small proportions. It is used as an alloying component to improve the properties of the metal. In addition to tin, the chemical composition of brass may contain lead, nickel, manganese and other metals that can improve the characteristics of the material.

Physical Properties

The characteristics of brass depend on additional alloying elements added to improve process parameters. For example, the density value varies in the range of 8300-8700 kg/m3.

The main physical properties of brass are:

- specific heat capacity when heated to 20 C is 0.377 kJ kg−1 K−1;

- specific electrical resistance 0.07 * 10−6 Ohm m;

- is not a ferromagnet, does not acquire magnetic properties when exposed to critical temperatures;

- melting point averages 900 degrees;

- high resistance to corrosion and destruction;

- durable;

- plastic,

- lends itself well to forging and processing;

- resistant to temperature changes.

Brass as a conglomerate of several metals has a weak conductivity of electric current. Composite metals create distortion of crystal lattices. The resulting voltage fields form the resistivity. Copper itself is an excellent conductor of electricity, so all wires are copper.

The melting point of a brass alloy depends on the percentage of zinc. The more zinc, the easier it is to melt brass.

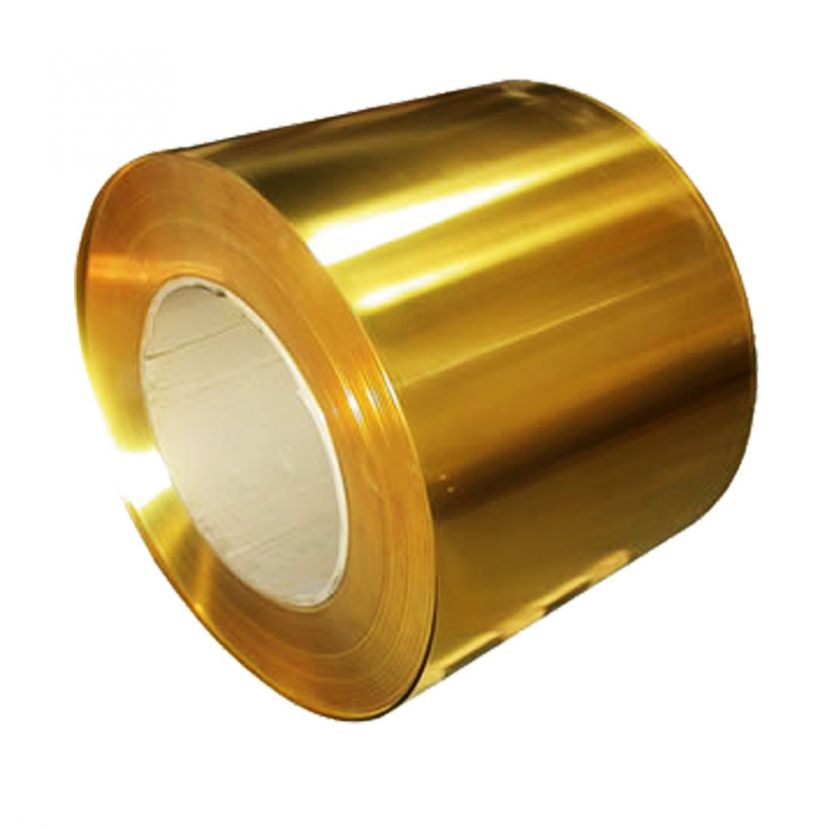

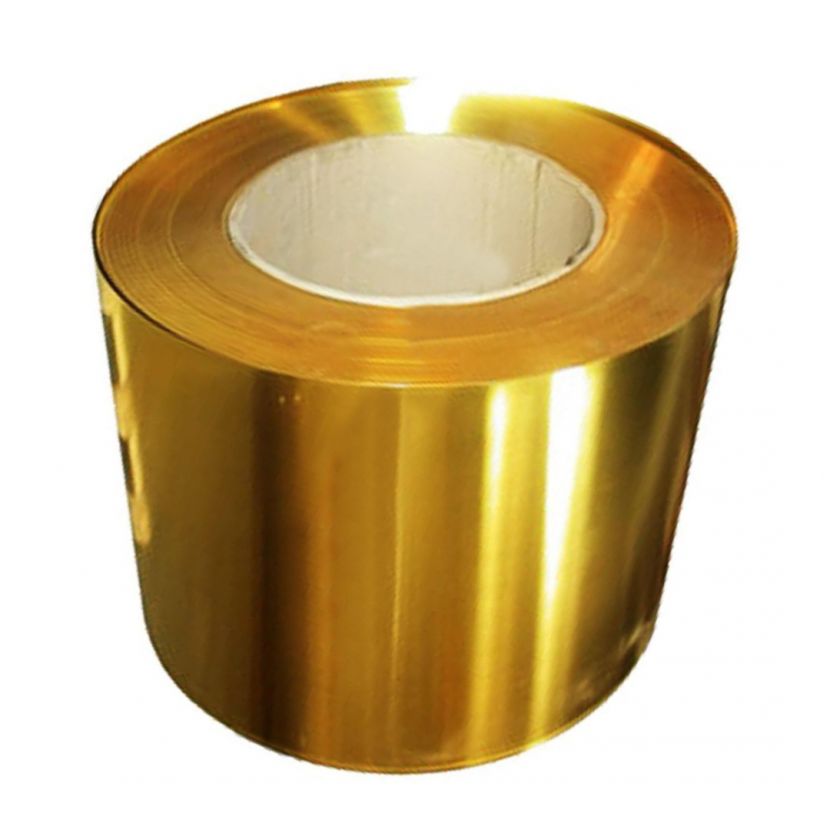

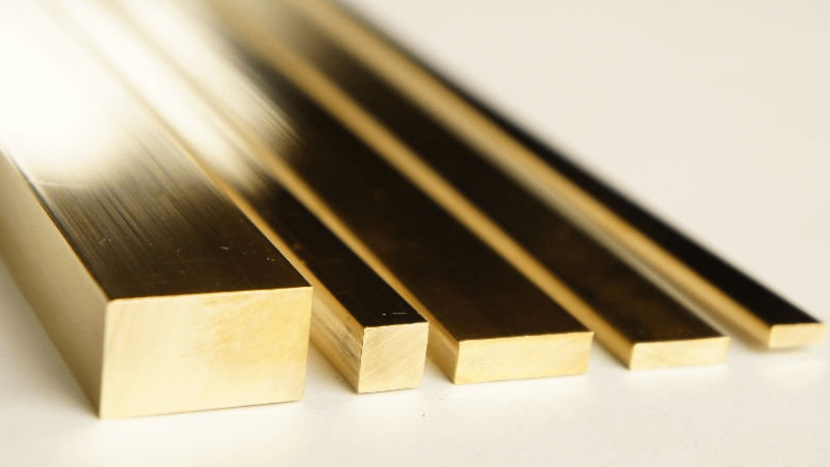

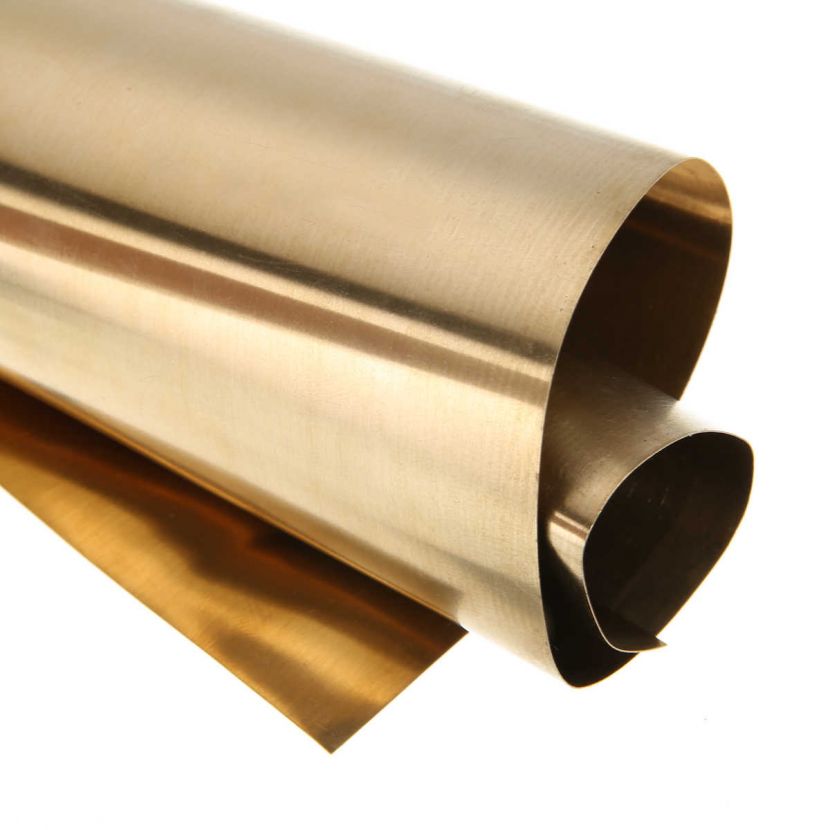

Brass rolled metal is well exposed to arc and gas welding. Well polished, rolled. Resists weathering better than pure copper.

Additions of bismuth and lead to the brass alloy reduce the elastic properties of the metal, making it brittle when exposed to high temperatures (at 500 degrees).

Influence of constituent elements

To expand the range of use of brass and improve its properties, alloying components are added to the alloy. Each constituent element has a specific effect:

- silicon lowers the hardness value, makes the material less durable, but resistant to wear during prolonged friction;

- manganese increases strength and resistance to corrosion;

- tin, aluminum and iron in small proportions are added to the alloy together with manganese to improve strength values;

- lead almost ceased to be added as an alloying element, it reduces the mechanical properties of the alloy, worsens ductility, elasticity;

- nickel increases corrosion resistance and makes it possible to use the metal in alkaline environments;

- aluminum, aluminum oxide creates a protective coating on the metal surface, which prevents oxidative processes from having a destructive effect;

- tin is a light metal, its addition improves the parameters of strength and resistance to corrosion.

An alloy with tin is widely used to create components for ships that constantly operate in sea water.

Production methods

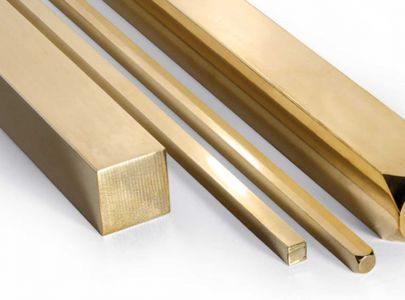

Brass is one of those conglomerates that respond well to processing methods - forging, stamping. At a low melting point, the metal shows good flow properties, so it is widely used in foundries.

When melting brass, zinc actively evaporates.

In the metallurgical industry, brass is mined in special refractory containers (crucibles), in melting furnaces, in which heat is transferred by radiation from gaseous products of fuel combustion. In furnaces, melting takes place in a short time and with economical energy consumption.

Alloy Applications

In ancient times, brass was used in jewelry because of its resemblance to natural gold. Due to its plasticity and good malleability for forging, coins were printed from it, jewelry and cases were made.

Brass alloys are improved by adding other metal components in order to improve the characteristics of rolled metal and expand the possibilities of its use in aggressive environments (in shipbuilding, in chemical shops).

In construction

Yellow metal has long established itself as a valuable material for creating parts for plumbing, pipes, appliances, and for the construction of various structures. Made from yellow metal

- fasteners (bolts and nuts, branch pipes, stamped parts);

- products for heat engineering structures, devices, equipment, condenser pipes;

- plumbing parts (faucet mixers, couplings, tees, fittings);

- furniture fittings (door handles, staples, door hinges).

Mechanical properties, resistance to moisture, strength and affordable price allow the use of yellow metal in various fields without fear that the material will collapse or rust.

Application in watches and art

In the watch industry, brass has found particularly widespread use due to the properties of flexibility, ductility and low cost. Products made of yellow metal look presentable, and the clock mechanism works reliably for many years. The material does not rust, does not oxidize, withstands a long stay in a humid environment, not succumbing to corrosive processes.

In the decorative arts, brass is valued for its ability to create designer pieces with the effect of gold presence. To create jewelry, such ornamental two-component brass alloys are used:

- green (zinc 40%);

- golden tompak (zinc 25%);

- classic yellow (zinc 33%).

Brass is an alloy with unique characteristics. Widely used in almost all designs used in difficult environmental conditions and aggressive environments. Brass jewelry looks luxurious, and with proper care does not lose its beauty for many years.